Producten

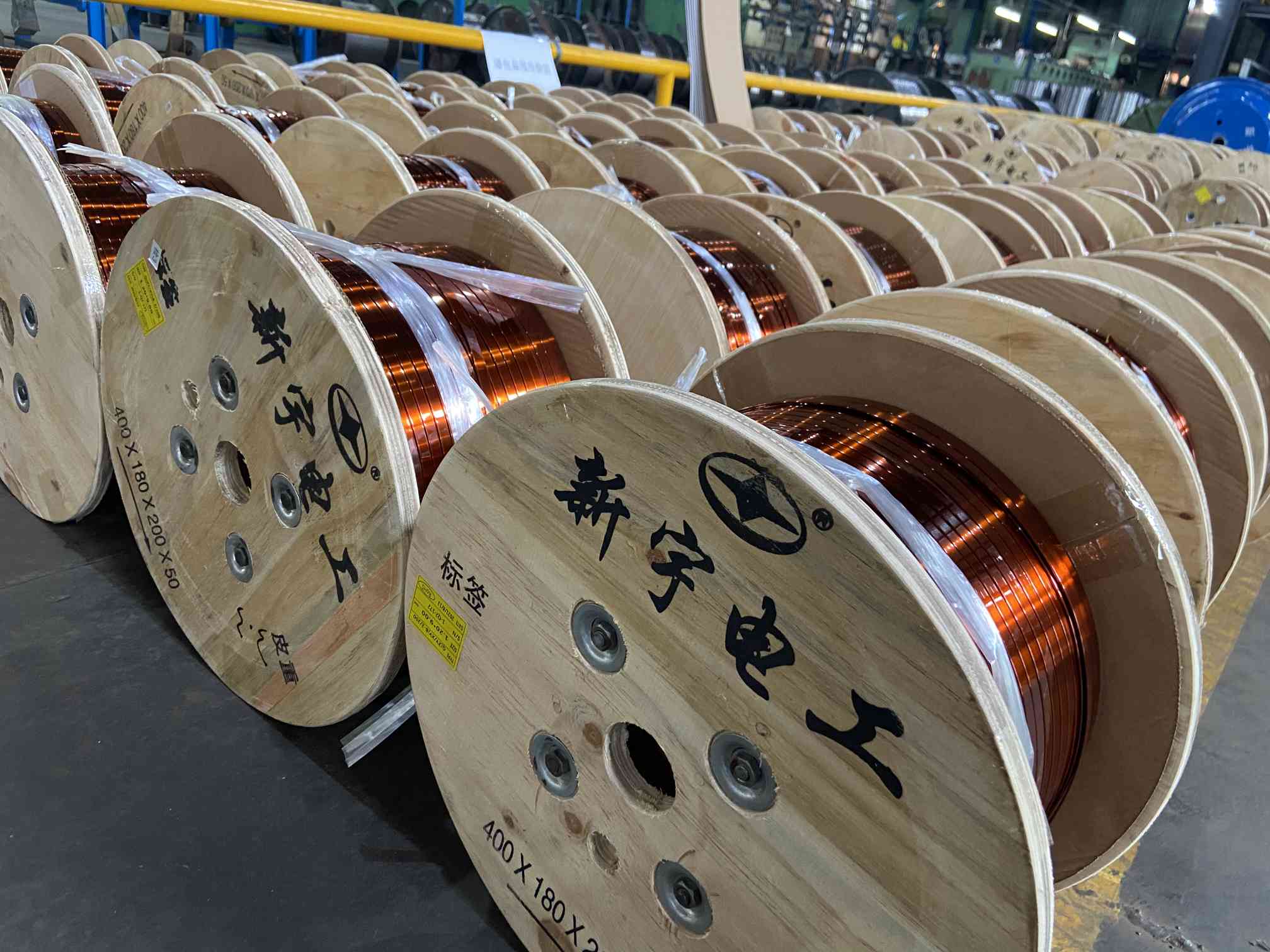

Geëmailleerde platte draad

Producttypen

● 130 klasse polyester geëmailleerde rechthoekige aluminium (koper) wikkeldraden

● 155 klasse gemodificeerde geëmailleerde rechthoekige aluminium (koper) wikkeldraden

● 180 klasse polyester-imide geëmailleerde rechthoekige aluminium (koper) wikkeldraden

● 200 klasse polyester-imide polyamide en zuur-imide composiet geëmailleerde rechthoekige aluminium (koper) wikkeldraden

● 120 (105) Klasse Acetaal Geëmailleerde Rechthoekige Aluminium (Koper) Wikkeldraden

Specificatie

Dikte van de geleider: a: 0,90-5,6 mm

Geleiderbreedte: b: 2,00~16,00 mm

Aanbevolen geleiderbreedteverhouding: 1,4

Elke gewenste specificatie is mogelijk, informeer ons hierover vooraf.

Standaard:GB, IEC

Spoeltype:PC400-PC700

Verpakking geëmailleerd rechthoekig draad:Palletverpakking

Certificering:UL, SGS, ISO9001, ISO14001, accepteren ook inspectie door derden

Kwaliteitscontrole:de interne norm van het bedrijf is 25% hoger dan de IEC-norm

Geleidermateriaal

● Zodra de grondstof van wikkeldraden verzacht koper is, is de elektrische weerstand bij 20 °C volgens de regelgeving in overeenstemming met GB5584.2-85 lager dan 0,017240 mm/m.

● Afhankelijk van de verschillende mechanische sterkte is de niet-proportionele reksterkte van de halfstijve koperen geleider Rp0,2 (>100~180) N/mm Rp0,2 (>180~220) N/m㎡ Rp0,2 (>220~260) N/m㎡

● Zodra het ruwe materiaal van wikkeldraden verzacht aluminium is, volgens de regelgeving in overeenstemming met GB5584.3-85, is de elektrische weerstand bij 20 °C lager dan 0,02801 Ω. mm/m

Afhankelijk van de verschillende vereisten van elektrische isolatie is de verfdikte beschikbaar van 0,06-0,11 mm of 0,12-0,16 mm, de dikte van de zelfklevende laag voor thermische verbinding van wikkeldraden is 0,03-0,06 mm.De optische verliestestfaciliteit met de naam TD11 kan worden gebruikt om het coatingproces te screenen, om zo de best uitgeharde coating te verkrijgen.

Indien u verdere wensen heeft met betrekking tot de dikte van de coating, verzoeken wij u ons vooraf te informeren.

Productdetails

Voordelen van geëmailleerd rechthoekig draad

1. Voldoet aan de ontwerpvereisten van lagere hoogte, kleiner volume, lichter gewicht, hogere vermogensdichtheid van elektronische en motorproducten, veel gebruikt in elektronica, elektrische apparaten, motoren, netwerkcommunicatie, slimme huizen, nieuwe energie, auto-elektronica, medische elektronica, militaire elektronica, lucht- en ruimtevaarttechnologie en andere gebieden.

2. Onder hetzelfde dwarsdoorsnedegebied heeft het een groter oppervlak dan de ronde geëmailleerde draad, wat effectief het "skin-effect" kan verminderen, het hoogfrequente stroomverlies kan verminderen en zich beter kan aanpassen aan het hoogfrequente geleidingswerk.

3. In dezelfde wikkelruimte,de toepassing van rechthoekige geëmailleerdedraad maakt de volledige snelheid van de spoelgleuf en de verhouding van het ruimtevolume hoger; vermindert effectief de weerstand, door een hogere stroom kan een hogere Q-waarde worden verkregen, beter geschikt voor werk met hoge stroombelasting.

4. De toepassing van rechthoekige geëmailleerde draadproducten, die een eenvoudige structuur hebben, goede warmteafvoerprestaties, stabiele prestaties, goede consistentie, kunnen nog steeds goed behouden blijven in een omgeving met hoge frequenties en hoge temperaturen.

5. Temperatuurstijgingsstroom en verzadigingsstroom; Sterke anti-elektromagnetische interferentie (EMI), lage trillingen, lage ruis, installatie met hoge dichtheid.

6. Hoge mate van groefvulling.

7. De productverhouding van de geleidersectie is meer dan 97%. De dikte van de hoekverflaag is vergelijkbaar met die van de oppervlakteverflaag, wat bevorderlijk is voor het behoud van de spoelisolatie.

8. Goede wikkeling, sterke buigweerstand, scheurt niet bij het wikkelen van de verffilm. Weinig kans op gaatjes, goede wikkelprestaties, geschikt voor diverse wikkelmethoden.

Toepassing van geëmailleerde rechthoekige draad

● Geëmailleerde platte draad wordt gebruikt in vermogenstransformatoren, AC UHV-transformatoren en DC-omvormertransformatoren.

● Hittebestendig geëmailleerd rechthoekig draad wordt gebruikt voor droge transformatoren.

● Elektrische motoren, generatoren en nieuwe energievoertuigen.

Spoel- en containergewicht

| Verpakking | Spoeltype | Gewicht/Spoel | Maximale laadhoeveelheid | |

| 20GP | 40GP/ 40NOR | |||

| Pallet (Aluminium) | PC500 | 60-65 kg | 17-18 ton | 22,5-23 ton |

| Pallet (koper) | PC400 | 80-85 kg | 23 ton | 22,5-23 ton |

PRODUCTCATEGORIEËN

Wij richten ons al 5 jaar op het leveren van mong pu-oplossingen.